The SDVC341 automatic frequency modulation vibration feeding controller with seven universal powers is here!

A must-see for industrial people around the world! The controller with seven universal powers is here!

SDVC341 automatic frequency modulation vibration feeding controller

Email: sales@cuhnj.com

Imagine a controller that can transcend language, voltage, and sensor limitations and easily cope with various industrial automation needs! Isn't it hard not to be moved~

With the in-depth development of the concept of Industry 4.0, modern manufacturing has higher and higher requirements for automation equipment. In order to meet this demand, CUH has launched a new controller with seven universal powers - "SDVC341 automatic frequency modulation vibration feeding controller."

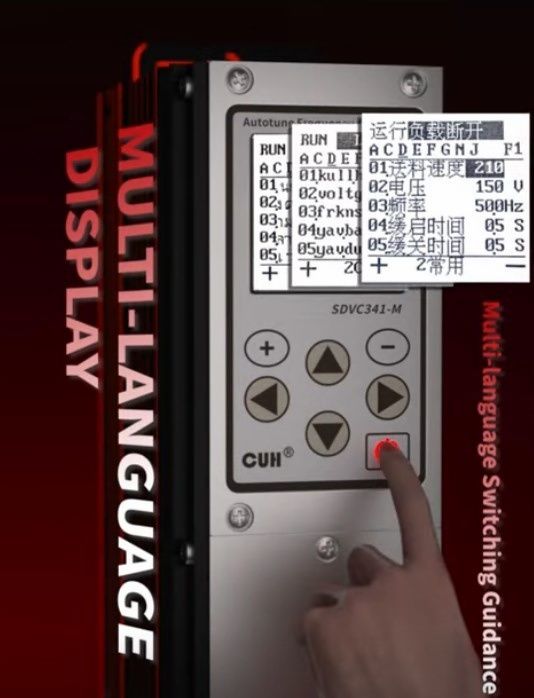

A、Multi-Language Display

The SDVC341 automatic frequency modulation vibration feeder controller comes in three languages by default: Chinese, English, and German. Customizable for any minor language, satisfying global language needs.

In a precision machinery manufacturing factory in Stuttgart, Germany, an experienced engineer is debugging a newly introduced automated assembly line. He was pleasantly surprised to find that the interface of the "SDVC341 automatic frequency modulation vibration feeder controller" could be easily switched to German, which made his debugging work extremely smooth. The engineer exclaimed: "Finally, I don't have to translate while flipping through the thick Chinese manual."

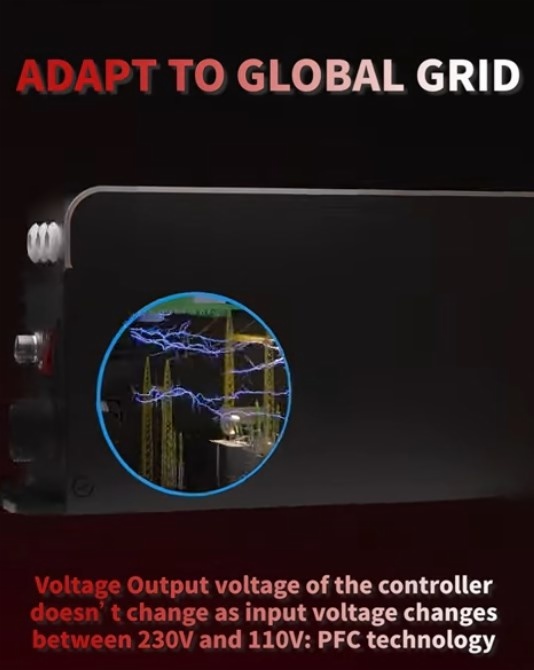

B、PFC Voltage Boost

With the expansion of global trade, more and more manufacturers need to export their products to the world, which requires the equipment to be able to operate stably under different power grid voltage environments around the world.

PFC technology adapts to any grid voltage worldwide, enabling every country to use their own power supply system. Whether it is a 110V power supply or 220V power supply, it can operate freely, overcoming the difficulty of power grid compatibility in one fell swoop, helping enterprises to easily cope with the challenges of equipment export.

C、Sensor Universality

In industrial environments, production processes may be adjusted according to changes in market demand. At this time, if the controller can support multiple sensors, engineers can replace sensors at any time according to actual needs without having to replace the entire control system.

The "SDVC341 automatic frequency modulation vibration feeding controller" can meet this production demand. The great sensor compatibility brings very convenient flexibility to production. They can adapts to both NPN and PNP type sensors, which not only simplifies the configuration process of the equipment but also improves the flexibility of the production line.

D、Parameter Sharing

The "SDVC341 automatic frequency modulation vibration feeding controller" relies on the CUHBus-DS® communication protocol developed by CUH. After simple wiring and networking, only one sensor is required to achieve eight shared control signals, saving cumbersome wiring work. Especially when the factory is engaged in large-scale production, this feature can significantly shorten the equipment debugging time and speed up the production rhythm.

E、Sensor Sharing

Relying on the CUHBus-DS® communication protocol developed by CUH, after a sensor is connected to a controller, only one sensor is required to achieve eight shared control signals, saving cumbersome wiring work, greatly improving production efficiency.

F、Wide Output Frequency Range

The SDVC341 supports an ultra-wide frequency output range from 5Hz to 999.9Hz, enabling full-band output frequency support for loads, achieving universal applicability across all frequency bands.

G、Load Universality

It can automatically track and adapt to any load, ensuring universal applicability under various load conditions.

END

The seven globally applicable innovative designs of the "SDVC341 Automatic Frequency Modulation Vibration Feeder Controller" provide unprecedented convenience and reliability for industrial automation.

The SDVC341 Automatic Frequency Modulation Vibration Feeder Controller is not just a controller, but a device that can provide efficient solutions for your automated production, allowing companies to easily cope with the challenges of global production and help the global manufacturing industry achieve high-quality feeding freedom.