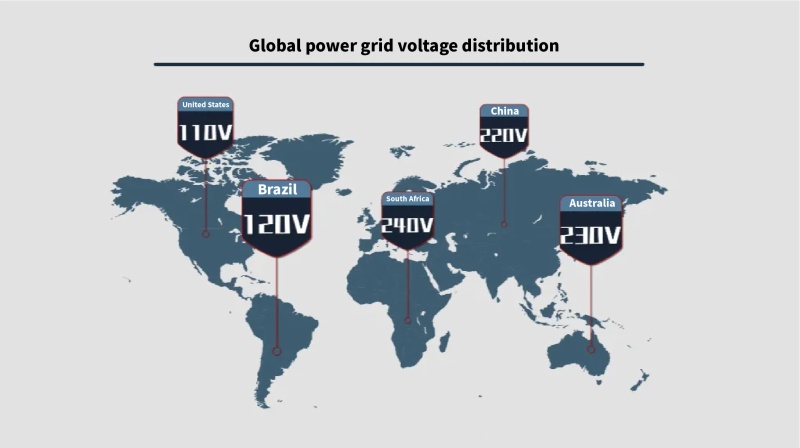

No transformer is required, and the feed controller is suitable for all voltages worldwide !

If traditional automation equipment needs to be used globally, it often needs to be equipped with an external transformer to cope with different grid voltage standards in various countries, which not only increases costs but may also affect the energy efficiency of the equipment. However, the SDVC341-M vibratory feeder controller launched by CUH does not need to worry about voltage matching issues. At the same time, it also reduces additional hardware investment, saves costs, and can significantly improve the versatility and market competitiveness of the equipment.

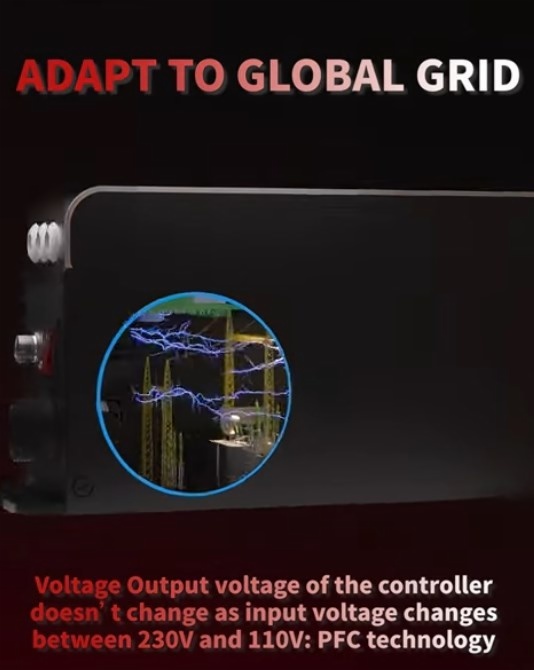

No external transformer is required, adapt to global voltage

"SDVC341 automatic frequency modulation vibration feeding controller" adopts advanced PFC technology. Whether the 220V European power grid or the 110V US and Japanese power grid, no external transformer is required, and the equipment is plug-and-play.

One-time debugging, global applicability

The SDVC341M vibratory feeder controller has global voltage compatibility, so engineers only need to set it up once before the equipment leaves the factory and then safely ship it overseas. After receiving the equipment, customers only need to connect it to the local power grid without any additional adjustment steps.

Typical Customer Case

Mr. Zhang, the sales manager of a well-known electronic equipment manufacturer in Shenzhen, welcomed a business opportunity across the Pacific in midsummer June: an important order from the United States, requiring delivery in August. Although everything went smoothly during the debugging process in China, the equipment had an unexpected abnormality when it was installed in the United States. After investigation, the truth slowly surfaced: It turned out that this was a fault caused by power differences. The United States uses the 110v power grid standard, while China uses the 220v power grid standard, so there was an operational failure.

Faced with this sudden accident, Mr. Zhang quickly contacted CUH, which is famous for its global technical support, for help. After understanding the situation, the domestic after-sales service helped Mr. Zhang contact the American distributor Manager Bryant through the overseas sales manager. The American distributor Manager Bryant contacted the American customer as soon as possible and agreed to conduct technical rescue the next day.

The next morning, Bryant brought the "SDVC341-M feeder remote control" with a universal global voltage function to the customer's site. With the built-in advanced voltage stabilization technology, it ensured that the equipment could operate stably at 110V voltage, successfully overcoming the grid compatibility problem. The customer also showed a satisfied smile and gave us a thumbs-up.

Looking to the future, CUH will continue to listen to and dig deep into customer needs with a keen global vision, and unnervingly explore and move forward on the road of technological innovation.