Why Long-Termism Makes Our Controllers Pricier: Understanding the Value of Quality and Sustainability

On Tuesday afternoon, the salesperson came to me with a sad face and said, "Can you promote the most professional equipment and good materials used in our controllers?"

Later, I learned that he had just quoted the price to the customer, and the customer left a sentence "You are more expensive than other companies" and ignored him...

So, today we will arrange the second question of the 30 questions about the product: "Why is our controller more expensive than other companies?"Similarly, there are some ideas when selecting a controller.

01

Choose the most authoritative and professional equipment

The vibration feeder controller contains complex electronic components and precision mechanical structures. To accurately control parameters such as adjusted frequency, amplitude and material flow speed, high-precision processing equipment must be used.

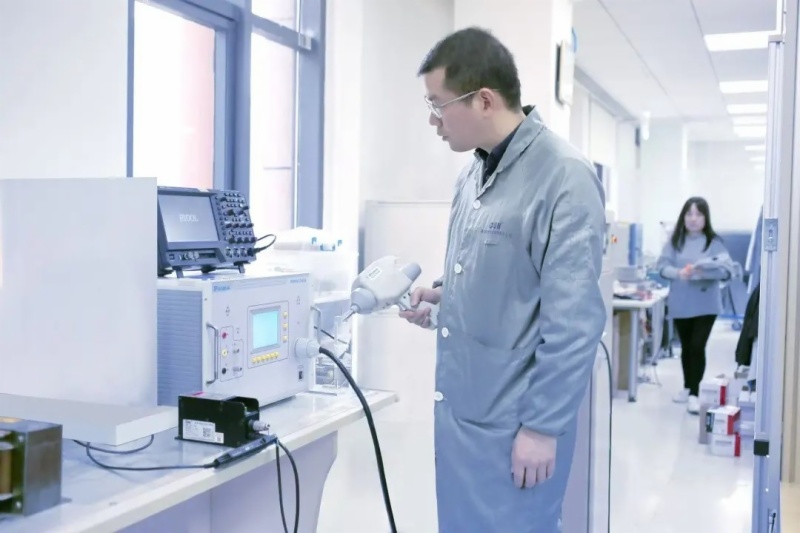

Therefore, CUH has adopted the most advanced and authoritative equipment and technology. For example, in the hardware design stage, we use the most advanced oscilloscopes to verify the performance of electronic components and complete a series of rigorous tests, including the startup process, stable operation period, and response under load changes, to ensure that all indicators of our controllers meet the design requirements.

02

Choose the best and most reliable materials

The production of a controller involves various materials such as the shell and circuit board substrate. Different materials will directly affect the controller's service life and the production line's safety. Take aviation plugs as an example. Most of the materials on the market are metal materials. We use PA66 materials with better pressure resistance and insulation to prevent the operator from taking safe grounding measures when using argon arc welding to weld the vibratory bowl feeder. In addition, our shells and parts have undergone strict process inspections to ensure that the materials are qualified before they can be assembled and used so that safe production can be implemented.

03

Provide the most reliable and reliable after-sales guarantee

The vibration feeder controller is not a one-time product. Whether it is the early equipment debugging or the failure or error during operation, it requires strong after-sales support. What we provide to customers is not only 7*24 hours after-sales service support but also the only supplier in the industry that provides a lifetime product warranty.

In recent years, a word called "long-term" has emerged. So, when choosing a vibration feeder controller, what kind of long-term should we follow?

The answer is:

Can the equipment meet the needs in the long term?

Have the materials used been carefully studied?

Is the after-sales service reliable in the long term?

What CUH has always adhered to is "long-term", focusing on providing customers with long-term products, long-term value, and long-term services.

Finally, you are welcome to consult any controller issues, always online.